Auto Stocker System

본문

-

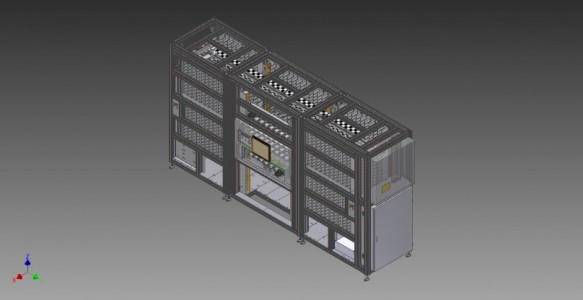

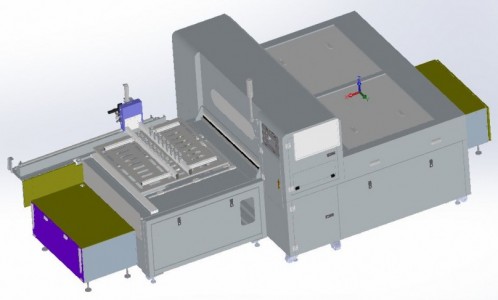

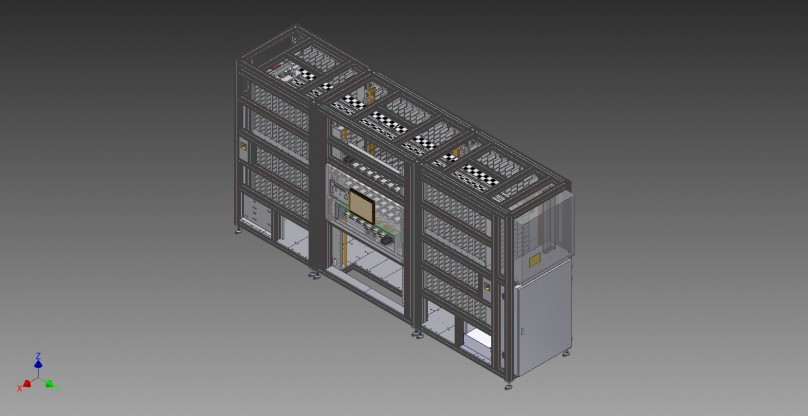

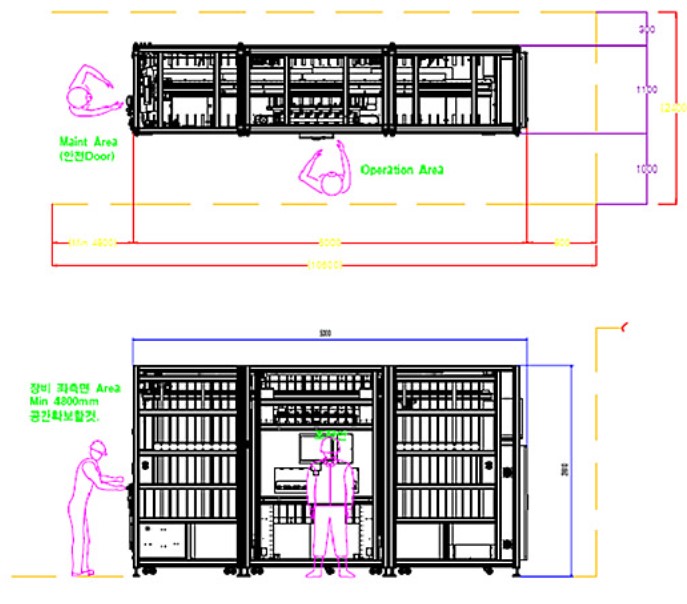

Overview of Equipment

This equipment is used to warehouse and deliver parts of facilities used in the semiconductor process automatically and manually. There are the monitor that controls facilities (Resistive touch panel), the control panel that controls power supply, and the outlet that parts are warehoused and delivered outside the device. There are ‘emergency shutdown’ switches on three positions on the front for safety. The door interlock device (The key type. Users must have a key when they enter inside.) is attached to the side of the doorway. The area sensor that senses human bodies when kit boxes are in and out are attached to the outlet on the front.

Specifications of Equipment

- Size : 5050mm x 1,100mm x 2,600mm (W x D x H)

- Load Volume : 1,400EA ~ 3,000EA

- Tack Time : 18sec/EA

- Simultaneous discharge quantity : 1EA ~ 10EA

- Kit input and sense method : Vison

- warehousing and delivery method : Manual, Semi Auto, Auto

- There is the axis that transports the kit box from storage space to discharge space and the pneumatic cylinder operated for discharge and input is installed inside the device.

- There is the reader that recognizes 2D bar codes of a C kit on the top of the outlet and a CCD camera gets to grasp if there is the C kit in the Kit box when parts are input.